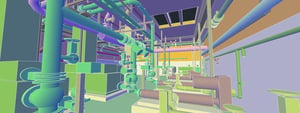

ScanToCAD with SOLIDWORKS - Integrate existing 3D environments into CAD

Start: 9. Mai 2025, 18:00 Uhr

Smap3D ScanToCAD ensures that designers will now be able to more quickly transfer existing physical surfaces and geometry from 3D scans/point clouds into the CAD, instead of drawing these themselves.

With Smap3D ScanToCAD, mulitple 3D scans can be referenced or the individual scans can be integrated into an overall project. The software transfers the selected 3D geometry directly to SOLIDWORKS and Solid Edge.

The greatest benefit is that, it is not necessary to import the entire point cloud with its high volume of data into the CAD. Instead, the designer transfers selected standard geometry with Smap3D ScanToCAD.

Smap3D Plant Design GmbH

Am Marktplatz 7

93152 Nittendorf

Germany

Tel.: +49 9404 963910

E-Mail: info@smap3d.com

Smap3D Plant Design, LLC.

260 Arbor Springs N Dr.

Newnan, GA30265

USA

Phone: +1 408 484 6404

E-mail: info@smap3d.com